Rexon Pipe Fittings, a company located in Mumbai, India, and a prominent manufacturer and exporter in the premium Stainless Steel 316 Butt-Welded Schedule (SCH) 80 Pipe Fittings range, is an enterprise founded in India. Precision fabrication is the feature of our fittings what will allow them to cope with high pressure and to have corrosion resistance as unbeatable advantage where long-lasting performance is imperative. These fittings, which originated from 316 stainless steel, are made to withstand the highest requirements in environments where reliability is vitally important. The SCH 80 classification is for pipe walls of greater thickness and than the type usually used, providing for added strength and pressure capability to dealing with higher pressure applications. Our SCH 80 pipe fittings are diverse and people can find elbow, Tee, reducer, stub ends and other connectors in our catalog. Therefore, the whole industry of petrochemical, chemical processing, oil and gas, and marine can use them in piping system.

Rexon Pipe Fittings is a manufacturer that is dedicated to implementing quality standards and satisfying customers. By offering products identified as designed and manufactured in accordance with international standards, we go beyond our customers' expectations. Just as trust Rexon's for high-grade Stainless Steel 316 Butt-Welded Schedule 80 Pipe Fittings; these parts offer you reliable performance and long-term durability, in your piping systems.

Our SS316 SCH 80 pipe fittings are manufactured through the use of the best qualities raw materials and the latest technology. This helps us to give our fittings the necessary toughness, durability and resistance to corrosion, which makes them perfectly suitable for many different industrial uses. You may need to have any kind of elbows, tees, reducers or any other fittings to match your specific requirements, which we provide for you.

SS 316 Elbow SCH 80 Butt-Welded Fittings provide stronger options for piping systems. Consisting of high-grade stainless steel, these fittings provide an enviable level of sustainability and corrosion resistance. They are seamlessly integrable into industrial complexes that require reliable tight-tight conditions.

316 SS TEE 80 Butt-Welded Fittings deliver quality and reliability for piping systems and are made of superior grade of stainless steel. Designed with a focus on durability and reliablity, these fittings result into seamless installation and an outstanding performance which can be trusted even in the most demanding industrial environments, offering a long-lasting function.

316 Reducer SS 316 SCH 80 Fittings butt-welded unite with the piping systems to ensure free-flowing materials. Constructed out of the long lasting stainless steel, these fittings are a corrosion-resistant and reliable source for the heavy-duty operations that are characterized by high intensity pressure distribution.

Sealing but-welded pumps for the piping systems, the 316 End Cap SS 316 SCH 80 Butt-Welded Fittings pump have been found to be the most robust. Although made from high-grade stainless steel, the fittings are perfectly designed to guarantee durability and corrosion and therefore ensures great performance in demanding industrial environments.

316 Stub End SS 316 SCH 80 Pipe Butt-Welded Fittings ensure durability for piping systems. Created from the best stainless steel, these fittings thus deliver reliability even in the toughest of circumstances. Those anti-corrosive properties and plenty of accurate engineering make them the perfect choice for industrial purposes.

SS Outlet 316 SCH 80 Butt-Welded fitting is the most reliable and robust item in the piping systems. The fittings, which are produced from quality stainless steel, possess excellent corrosion resistance and are well built, hence providing increased operational life in tough settings.

Discover the superiority of our vast selection of SCH 80 316 Stainless Steel Butt-Welded Pipe Fittings. Our Elbows, Tees, Reducers, and End Caps, carefully designed and corrosion resistant, are well engineered for longevity as well as corrosion resistant. Designed specially for installation to industrial piping systems that enable them to perform optimally even in harsh environments. Trust us to provide you with our 316 Stainless Steel SCH 80 fittings which offer quality constructed features and versatility to suit a variety of piping needs with ease and efficiency.

The Stainless Steel 316 Butt-Welded SCH 80 Pipe Fittings meet highest standards and quality to perform reliably in extreme pressure environments. As the fittings are manufactured from top-grade stainless steel, they are highly resistant to corrosion and durable. They feature precise dimensions and are built out of proper materials, ensuring that they are a tight and strong connection for piping systems operating under high pressure. These fittings have to go through rigorous testing in order to meet the requirements of the industry which ensures durability and safety in the important applications. Trust in the reliability of Stainless Steel 316 SCH 80 Butt-Welded Pipe Fittings which can stand the test of time and environment in the most demanding industrial settings.

| Butwelded Type | Butt-welded Fitting Standard |

|---|---|

| Type Of Fittings | 45 Deg, 90 Deg , 180 Deg. |

| Size | 1/2"NB TO 48"NB IN |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated |

| Grades | |

| Nickel Alloy | ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 (ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

| Stainless Steel | ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H. |

| Carbon Steel | ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Alloy Steel | ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91. |

| Duplex Steel | ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760. |

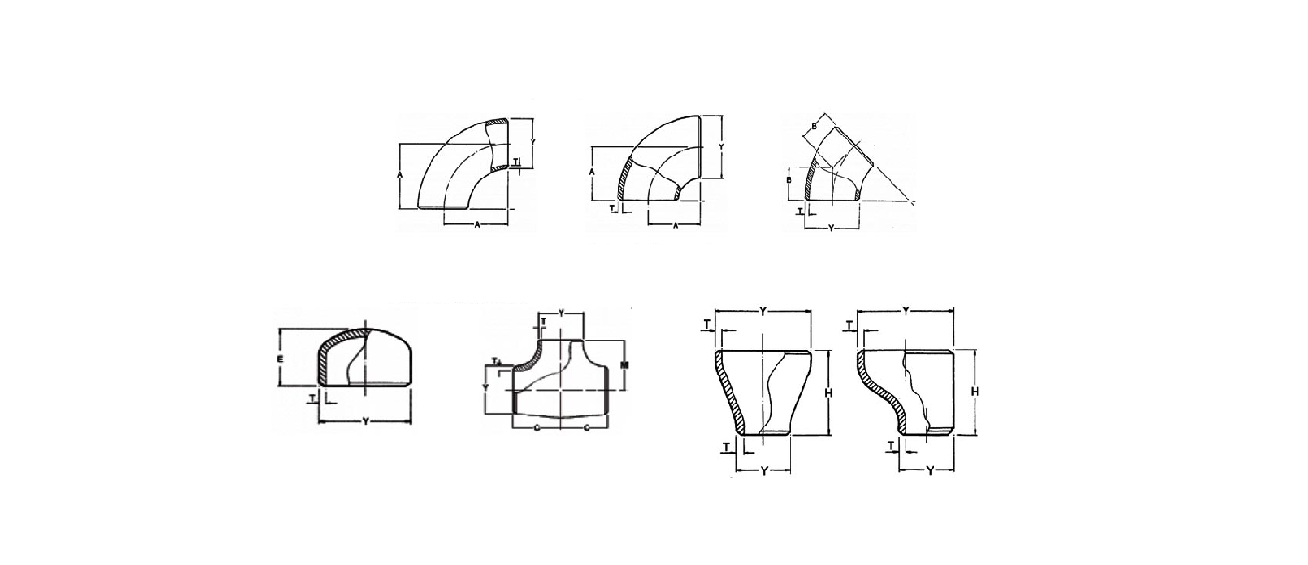

SS 316 Butt-Welded SCH 80 Pipe fittings are manufactured to ensure reliable performance in high-pressure environments, offering utmost robustness and resilience. The SCH 80 316 Stainless Steel Butt-Welded Pipe Fittings Design is a kind of diagram that will illustrate the exact configuration of the fittings so that the fitting can be installed accurately and the operation of the industrial applications will be reliable under the harsh environment.

A durable and suitable for tough industrial settings construction is provided by our choice of Butt-Welded Pipe Fitting and SCH 80 Butt-Welded Pipe Fitting made of SS 316. Generally, their chemical composition include chromium in the amount of 16-18% by weight, nickel in the amount of 10-14% and molybdenum in the amount of 2-3%, being responsible for the resistance to corrosion and strength. These joints meet the requirements of SCH 80 standards and so are able to perform with good reliability in high pressure piping systems.

| Element | AISI 316 (Standard) | AISI 316H (High Carbon) |

|---|---|---|

| Carbon (C) | 0.08% max | 0.04% - 0.10% |

| Chromium (Cr) | 16.0% - 18.0% | 16.0% - 18.0% |

| Nickel (Ni) | 10.0% - 14.0% | 10.0% - 14.0% |

| Manganese (Mn) | 2.0% max | 2.0% max |

| Silicon (Si) | 1.0% max | 1.0% max |

| Phosphorus (P) | 0.045% max | 0.045% max |

| Sulfur (S) | 0.03% max | 0.03% max |

| Nitrogen (N) | - | - |

| Iron (Fe) | Balance | Balance |

Robust and reliable Stainless Steel 316 SCH 80 Pipe Fittings that are commonly used in high-pressure applications are known for their Butt Welded design. This gives the fittings some of the best physical properties like high tensile strength, the ability to resist corrosion, and durability. With the tolerance in dimensions and high-quality finishing they provide, the fittings create zero-leakage cross-sealing elements which guarantee a secure fit in harsh factory environment. SS 316 pipe fittings in SCH 80 are very useful in situations where the fittings' strength and pressure performance are crucial.

| Grade | Tensile Str (MPa) min |

Yield Str 0.2% Proof (MPa) min |

Elong (% in 50mm) min |

Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40 | 95 | 217 |

| 316L | 485 | 170 | 40 | 95 | 217 |

| 316H | 515 | 205 | 40 | 95 | 217 |

Go through our SS 316 Butt-Welded SCH 80 Pipe Fittings Price List, effective from 1st March 2024, to avail of various pricing that are highly competitive.

| Description | Price In INR (Per Piece) |

|---|---|

| ASTM A403 WP | |

| 2" X SCH 40 | 325.00 |

| 3" X SCH 40 | 400.00 |

| 4" X SCH 40 | 600.00 |

| 6" X SCH 40 | 1350.00 |

| 8" X SCH 40 | 2400.00 |

| 10" X SCH 40 | 4500.00 |

| Country | Address |

|---|---|

UAE UAE |

Dubai |

UAE UAE |

Abu Dhabi |

Qatar Qatar |

Doha |

Saudi Arabia Saudi Arabia

|

Riyadh |

Saudi Arabia Saudi Arabia |

Jeddah |

Bahrain Bahrain |

Manama |

Kuwait Kuwait |

Kuwait City |

Oman Oman |

Muscat |

Saudi Arabia Saudi Arabia |

Eastern Province |

UAE UAE |

Sharjah |