Rexon is a prominent stainless steel manufacturer and exporter based in Mumbai, India and we deal in Schedule 80 (SCH) 304 Butt-Welded Pipe Fittings made up of high grade steel. All our products are carefully made in accordance with the international standards so that they can withstand the test of time, function appropriately, and deliver excellent performance. Stainless Steel SCH 80 Pipe Fittings Butt-Welded Schedule 304 are well-known for its superior corrosion resistant level and they can be used to service a wide range of industries, for example, chemical processing, food and beverage, pharmaceutical, etc. Equipped with precise engineering and top-quality building materials, we guarantee that our fittings will provide a steady and leak-free connection, bringing comfort to our customers.

We make customers happier by providing quality products and prompt services with competitive pricing at Rexon Pipe Fittings. We make not only elbows, tees, and reducers, but also other fittings for different needs. Trust Rexon Pipe Fittings which are leaders in quality and reliability of the Stainless Steel 304 Butt Welded Schedule (SCH) 80 Pipe Fittings. With every fitting, you experience a standard of excellence that we stand and guarantee with utmost satisfaction.

Our SS304 SCH 80 pipe fittings are manufactured through the use of the best qualities raw materials and the latest technology. This helps us to give our fittings the necessary toughness, durability and resistance to corrosion, which makes them perfectly suitable for many different industrial uses. You may need to have any kind of elbows, tees, reducers or any other fittings to match your specific requirements, which we provide for you.

The usage of top quality 304 stainless steel elbows for SCH 80 pipe fittings pushes for the durability and reliability. By butt welding, we can guarantee the connection of the parts to ensure the security of all branches of industry.

The Stainless Steel 304 SCH 80 Butt-Welded Fittings, such as tees, provide the piping systems in multiple industry fields with high-corrosion and ductile features as they are fit for systems which are under high levels of pressure.

Go with premium 304 reducers in 304 SCH80 butt-welded fitting for strong and enduring joints. The application of a perfect seal for the myriad industrial purposes is to guarantee a secure and leak free orifice.

The Stainless Steel 304 SCH 80 Butt-Welded Fittings can opaquely connect to the 304 end cap. These highly reliable and long-lasting fittings will serve with satisfaction for many years. This device has high wear and tear resistance, and also useful for cases where high quality connections are required.

Find Grade 304 Stub End Flanges for your industrial activities with high quality, 304 SCH80 Butt-Welded Fittings. Such fittings guarantee the durability and reliability of them in various units of usage.

Choose high-quality 304 Outlet SCH (80) Stainless Steel Fittings to meet your industrial applications. Such fittings have a durable construction with reliable and reusable connections meeting the needs of different uses.

The amazingly high performance and durability of the SCH 80 304 Stainless Steel Butt-Welded Pipe Fittings will allow Rexon Pipe Fittings to always exceed customer expectations. Designed with industrial use in mind, our Elbows, Tees, Reducers, and End Cap fittings are the backbone of system integrity and take on high pressure working environments. There is a reason why the piping systems from Rexon are in demand everywhere. They are well known for their excellent quality and reliability.

Rexon Pipe Fittings manufactures a high degree Stainless Steel (304) Butt-Welded SCH 80 Pipe Fittings that is designed to fulfill tough specifications for efficiency and reliability. These fittings are made of stainless steel of first class quality so as to provide you with dependable work in different industrial uses. Thanks to the accuracy of engineering, they smoothly align with resilient constructing arrangements, resulting in unbroken transmission and moving around the liquids. As an answer to the chance of high-pressure applications, these SCH 80 fittings are tough and resistant, and hence enduring in such environments to guarantee high performance. You can trust Rexon for highest level of efficiency and excellence in your piping locations.

| Butwelded Type | Butt-welded Fitting Standard |

|---|---|

| Type Of Fittings | 45 Deg, 90 Deg , 180 Deg. |

| Size | 1/2"NB TO 48"NB IN |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated |

| Grades | |

| Nickel Alloy | ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 (ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

| Stainless Steel | ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H. |

| Carbon Steel | ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Alloy Steel | ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91. |

| Duplex Steel | ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760. |

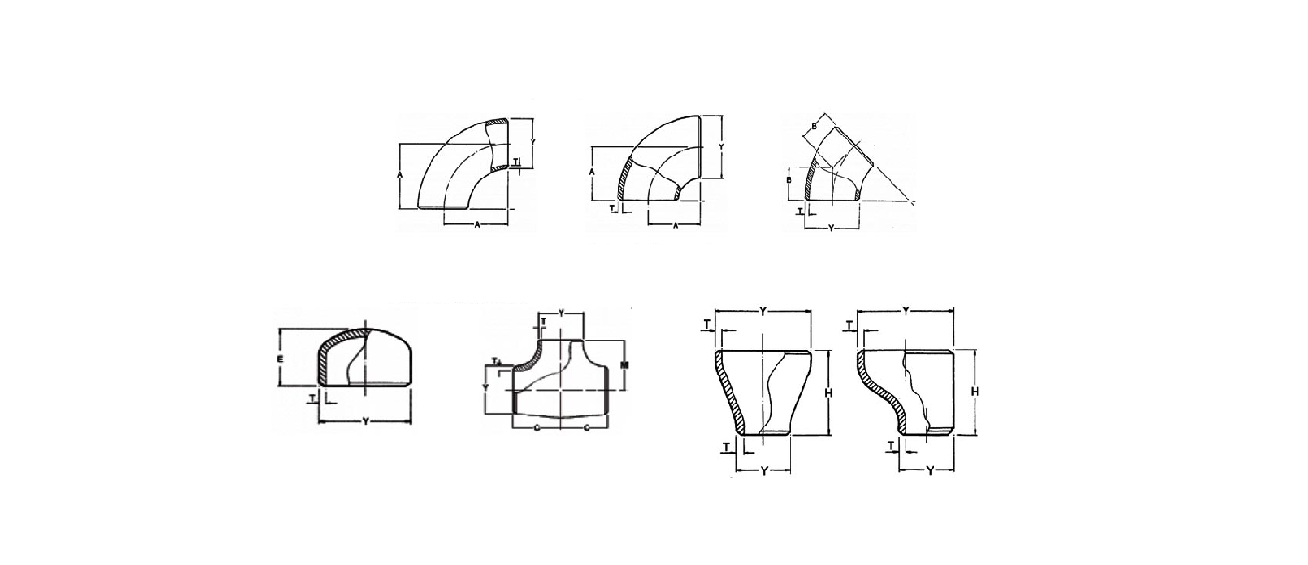

Investigate the solutions made of SS 304 Butt- Welded SCH 80 Pipe fittings crafted from specialists. These elbows, couplings, and adaptors guarantee smooth joining of the pipes, with no leaks. They are outfitted with a strong build and high efficiency, making them suitable for critical work. The SCH 80 304 Stainless Steel Butt-Welded Pipe Fittings Diagram further underscores their rugged design, providing the exact dimensions according to industry requirements with dependability and performance assured.

An SS 304 SCH 80 pipe fitting has its mechanical strength and electrochemical corrosion resistance owing to a mixture of chemical elements at carefully chosen levels. It will include at least 18% of chromium for forming a protecting layer and 8% of nickel for weldability and no more than a carbon percentage of 0.08% to avoid corrosion at high temperatures. This composition is in compliance with ASTM SS 304 and is designed to ensure dependable performance in harsh industrial conditions.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 304H | min. | 0.04 | – | – | – | – | 18.0 | – | 8.0 | – |

| max. | 0.10 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | |||

Stainless Steel 304 Butt Weld SCH 80 Pipe Fittings have amazing mechanical features that make them ideal for high-demand industrial applications. These materials have the combined properties of high tensile strength and excellent corrosion resistance to ensure longevity and reliability even in the most diverse environments. This greater malleability makes the overall installation and maintenance process much easier, and the surface finish is smooth which helps decrease friction and raise the flow rate of fluids. These couplings are meant to stand up to elevated temperatures and pressures; as such they have great efficiency and longevity.

| Grade | Density (kilogram/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity(W/m.K) | Specific Heat 0-1000C(J/kilogram.K) | Electrical Resistivity (n.m) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| ASTM A403 WP 304 Elbow | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

Our new price sheet for Welded Butt SCH 80 Pipe Fittings of SS 304, effective from 1st of March 2024 bears the best commercial rates for superior quality fittings. Contact us for the updated pricing, and we will be happy to reserve your requirement of high-end stainless steel fittings for your industrial purposes.

| Description | Price In INR (Per Piece) |

|---|---|

| ASTM A403 WP | |

| 2" X SCH 40 | 325.00 |

| 3" X SCH 40 | 400.00 |

| 4" X SCH 40 | 600.00 |

| 6" X SCH 40 | 1350.00 |

| 8" X SCH 40 | 2400.00 |

| 10" X SCH 40 | 4500.00 |

| Country | Address |

|---|---|

UAE UAE |

Dubai |

UAE UAE |

Abu Dhabi |

Qatar Qatar |

Doha |

Saudi Arabia Saudi Arabia

|

Riyadh |

Saudi Arabia Saudi Arabia |

Jeddah |

Bahrain Bahrain |

Manama |

Kuwait Kuwait |

Kuwait City |

Oman Oman |

Muscat |

Saudi Arabia Saudi Arabia |

Eastern Province |

UAE UAE |

Sharjah |