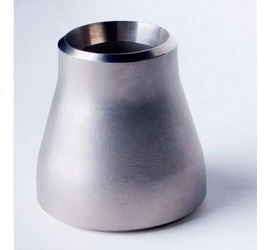

Buttwelded Reducer Pipe Fitting, AISI 310H Stainless Steel is a pipe fitting that joins two pipes of varying diameters. A reducer pipe fitting shrinks the pipe from a bigger to a smaller bore However, a buttwelded reducer pipe fitting is included in the welding of both ends of the pipes forming a seamless and leak-free welded joint. AISI 310H is a high carbon version of 310 stainless steel with superior oxidation and corrosion resistance at elevated temperatures. AISI 310H stainless steel has higher strength and toughness than AISI 316S, with a better technological serviceability. It can be used for furnace parts, heat exchangers, oil burners as well as other applications where high strength is required. The high-quality raw materials and advanced technology are used to manufacture AISI 310H buttwelded reducer pipe fitting that is stainless steel. The pipe fitting is such that it conforms to the specifications of ASTM A403, ANSI B16.9, MSS SP-43, and MSS SP-79. The choice of pipe fitting by the customer determines the size, shape and schedule. Quality and performance tests are conducted on the pipe fitting before delivery to guarantee that a high-quality product is received and will stand up through years of service.

310H is highly carbon-modified 310 stainless steel that offers superior resistance to oxidation and corrosion under high temperatures. Among the available fittings are AISI 310H buttwelded reducer pipe fittings, which can be used in furnace parts, heat exchangers and oil burners that require high strength and endurance. These particular fittings are offered various sizes and schedule depending on customers’ orders.

Rexon Pipe fittings offers stainless steel Buttwelded Concentric Reducer pipe fittings. They have two opposite ends with varying sizes that connect pipes of different thicknesses and align the axis. These are commonly used to change the pipe diameter and flow rate of the most diverse piping systems.

Rexon produces and provides Buttwelded Eccentric Reducer pipe fittings that are stainless steel fittings characterized by having two ends with different diameters and a slanted centerline.

However, Hotweld Reducer pipe fittings are simply fittings made by Rexon Pipe fittings and supplied by the company called Rexon Pipe Fittings, which has two ends with different diameters and a shorter end than normal reducers, all made of stainless steel.

Rexon Pipe fittings involves in the manufacture and supply of Buttwelded Long-End Reducer pipe fittings’ stainless steel fittings that have two ends with different diameters and a longer end than normal reducers.

The specifications of Stainless Steel buttwelded reducer pipe fitting are based on 310H, which define the dimensions, tolerances, and material grades of forged and seamless tubular products made of wrought austenitic stainless steel.

| Specification | Description |

|---|---|

| Material Grade | AISI 310H (UNS S31009) stainless steel |

| Size Range | Specified in nominal pipe sizes (NPS) or millimeters |

| Wall Thickness | Conforms to the appropriate standard (e.g., ASME B16.9) - Specified in schedule numbers or millimeters |

| Manufacturing Standards | Conforms to recognized standards, such as ASME B16.9 (for stainless steel fittings) |

| Pressure Rating | Varies with material, wall thickness, and size - Typically designated by class numbers (e.g., Class 150, Class 300) |

| End Connections | Beveled ends for welding - Bevel angle typically 37.5 degrees |

| Surface Finish | Exterior and interior surfaces free from defects - Welds properly formed and inspected |

| Heat Treatment | Post-weld heat treatment (PWHT) may be necessary for certain high-temperature applications |

| Testing and Inspection | Visual inspection, dimensional checks, non-destructive testing (e.g., radiographic, ultrasonic) - Material testing (e.g., PMI) |

| Marking | Clearly marked with size, material grade, manufacturer's name/logo, and relevant standards |

| Certification | Manufacturer provides material certificates, test reports, and other documentation to confirm compliance with specifications and standards |

The physical properties that can be attributed to 317/317L SS buttwelded reducer pipe fitting, stainless steel fittings that have excellent thermal conductivity and low thermal expansion, include density, specific heat and modulus of elasticity.

| Property | Typical Values for Stainless Steel Butt-Welded Reducer Pipe Fittings |

|---|---|

| Density | 7.7 - 8.0 g/cm³ |

| Melting Point | 1400 - 1450°C (2552 - 2642°F) |

| Thermal Conductivity | 14 - 20 W/(m·K) |

| Specific Heat Capacity | 500 J/(kg·K) |

| Electrical Conductivity | Low compared to metals like copper or aluminum |

| Magnetic Properties | Non-magnetic in the annealed condition, may become magnetic after cold working or heat treatment |

| Coefficient of Thermal Expansion | 16 - 17 μm/m·K |

| Modulus of Elasticity (Young's Modulus) | Approximately 190 GPa (27.6 x 10^6 psi) |

| Hardness | Varies based on alloy and heat treatment, typically 70 - 200 HV (Vickers hardness) |

| Tensile Strength | Varies based on grade and manufacturing, typically 515 - 760 MPa (74,700 - 110,200 psi) |

| Yield Strength | Varies based on grade and heat treatment, typically 205 - 550 MPa (29,700 - 79,800 psi) |

| Ductility | Excellent, allowing for complex forming without significant loss of strength |

| Corrosion Resistance | Highly corrosion-resistant, suitable for use in corrosive environments |

| Appearance | Bright, reflective, and silvery appearance |

| Weldability | Generally weldable, with the welding process chosen based on grade and application |

317/317L SS buttwelded reducer pipe fitting is a stainless steel fitting that contains components such as chromium, nickel, carbon and other elements that have good corrosion resistance and tensile strength.

| Element | 317 Stainless Steel (%) | 317L Stainless Steel (%) |

|---|---|---|

| Carbon (C) | 0.08 max | 0.03 max |

| Chromium (Cr) | 18.0 - 20.0 | 18.0 - 20.0 |

| Nickel (Ni) | 11.0 - 15.0 | 11.0 - 15.0 |

| Manganese (Mn) | 2.0 max | 2.0 max |

| Silicon (Si) | 0.75 max | 0.75 max |

| Phosphorus (P) | 0.045 max | 0.045 max |

| Sulfur (S) | 0.03 max | 0.03 max |

| Molybdenum (Mo) | 3.0 - 4.0 | 3.0 - 4.0 |

| Iron (Fe) | Balance | Balance |

| Description | Price In INR (Per Piece) |

|---|---|

| ASTM A403 WP | |

| 2" X SCH 40 | 325.00 |

| 3" X SCH 40 | 400.00 |

| 4" X SCH 40 | 600.00 |

| 6" X SCH 40 | 1350.00 |

| 8" X SCH 40 | 2400.00 |

| 10" X SCH 40 | 4500.00 |

| Country | Address |

|---|---|

UAE UAE |

Dubai |

UAE UAE |

Abu Dhabi |

Qatar Qatar |

Doha |

Saudi Arabia Saudi Arabia

|

Riyadh |

Saudi Arabia Saudi Arabia |

Jeddah |

Bahrain Bahrain |

Manama |

Kuwait Kuwait |

Kuwait City |

Oman Oman |

Muscat |

Saudi Arabia Saudi Arabia |

Eastern Province |

UAE UAE |

Sharjah |