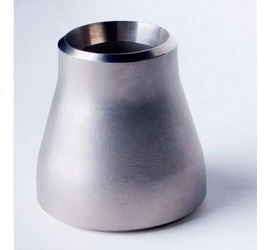

Rexon, one of the major producers, gives AISI 347/347H Stainless Steel ButtWelded Reducer Pipe Fittings. These highly engineered connectors improve fluid flow and strength in piping systems. Situated from reliable AISI 347/347H stainless steel, they perform well in many industrial cases with remarkable corrosion resistance. Rexon provides our customers with accuracy, competitive pricing, and timely delivery of reducer pipe fittings of the highest quality, which is why we are the best option. Select Rexon for superior connections that improve project performance and longevity.

AISI 347/347H stainless steel butt-welded reducer pipe fitting is common in the industries requiring high pressure and temperature like chemical, petrochemical, oil and gas, and power generation.

On the other hand, Rexon Pipe fittings manufactures buttwelded Concentric Reducer pipe fittings, which are stainless steel fittings that have two openings of different diameters that join two pipes of different sizes and align the centerline. They are widely employed to change the pipe diameter and flow in a range of piping systems.

Eccentric Reducer pipe fittings manufactured by Rexon Pipe fittings are stainless steel fittings that possess two orifices with different diameters and a tilted centerline that links pipes of different calibers.

Rexon Pipe fittings offers Buttwelded Short-End Reducer pipe fittings which are two-opened stainless steel fittings that have short end as compared to standard reducer.

Rexon Pipe fittings manufacture buttwelded Long-End Reducer pipe fittings, which are reducer fittings made of stainless steel and have two ends with different diameters and a longer end than regular reducers.

The technical characteristics of Stainless Steel buttwelded reducer pipe fitting are based on AISI 347 that provides dimensions, tolerances, and material grades of austenitic stainless steel fittings that are produced from forged and seamless tubular products.

| Specification | Description |

|---|---|

| Material Grades | AISI 321 (UNS S32100), AISI 321H (UNS S32109) |

| Size Range | Specified in nominal pipe sizes (NPS) or millimeters |

| Wall Thickness | Conforms to the appropriate standard (e.g., ASME B16.9) - Specified in schedule numbers or millimeters |

| Manufacturing Standards | Conforms to recognized standards, such as ASME B16.9 (for stainless steel fittings) |

| Pressure Rating | Varies with material, wall thickness, and size - Typically designated by class numbers (e.g., Class 150, Class 300) |

| End Connections | Beveled ends for welding - Bevel angle typically 37.5 degrees |

| Surface Finish | Exterior and interior surfaces free from defects - Welds properly formed and inspected |

| Heat Treatment | Post-weld heat treatment (PWHT) may be necessary for certain applications |

| Testing and Inspection | Visual inspection, dimensional checks, non-destructive testing (e.g., radiographic, ultrasonic) - Material testing (e.g., PMI) |

| Marking | Clearly marked with size, material grade, manufacturer's name/logo, and relevant standards |

| Certification | Manufacturer provides material certificates, test reports, and other documentation to confirm compliance with specifications and standards |

The physical properties that can be attributed to 317/317L SS buttwelded reducer pipe fitting, stainless steel fittings that have excellent thermal conductivity and low thermal expansion, include density, specific heat and modulus of elasticity.

| Property | Typical Values for Stainless Steel Butt-Welded Reducer Pipe Fittings |

|---|---|

| Density | 7.7 - 8.0 g/cm³ |

| Melting Point | 1400 - 1450°C (2552 - 2642°F) |

| Thermal Conductivity | 14 - 20 W/(m·K) |

| Specific Heat Capacity | 500 J/(kg·K) |

| Electrical Conductivity | Low compared to metals like copper or aluminum |

| Magnetic Properties | Non-magnetic in the annealed condition, may become magnetic after cold working or heat treatment |

| Coefficient of Thermal Expansion | 16 - 17 μm/m·K |

| Modulus of Elasticity (Young's Modulus) | Approximately 190 GPa (27.6 x 10^6 psi) |

| Hardness | Varies based on alloy and heat treatment, typically 70 - 200 HV (Vickers hardness) |

| Tensile Strength | Varies based on grade and manufacturing, typically 515 - 760 MPa (74,700 - 110,200 psi) |

| Yield Strength | Varies based on grade and heat treatment, typically 205 - 550 MPa (29,700 - 79,800 psi) |

| Ductility | Excellent, allowing for complex forming without significant loss of strength |

| Corrosion Resistance | Highly corrosion-resistant, suitable for use in corrosive environments |

| Appearance | Bright, reflective, and silvery appearance |

| Weldability | Generally weldable, with the welding process chosen based on grade and application |

317/317L SS buttwelded reducer pipe fitting is a stainless steel fitting that contains components such as chromium, nickel, carbon and other elements that have good corrosion resistance and tensile strength.

| Element | 317 Stainless Steel (%) | 317L Stainless Steel (%) |

|---|---|---|

| Carbon (C) | 0.08 max | 0.03 max |

| Chromium (Cr) | 18.0 - 20.0 | 18.0 - 20.0 |

| Nickel (Ni) | 11.0 - 15.0 | 11.0 - 15.0 |

| Manganese (Mn) | 2.0 max | 2.0 max |

| Silicon (Si) | 0.75 max | 0.75 max |

| Phosphorus (P) | 0.045 max | 0.045 max |

| Sulfur (S) | 0.03 max | 0.03 max |

| Molybdenum (Mo) | 3.0 - 4.0 | 3.0 - 4.0 |

| Iron (Fe) | Balance | Balance |

| Description | Price In INR (Per Piece) |

|---|---|

| ASTM A403 WP | |

| 2" X SCH 40 | 325.00 |

| 3" X SCH 40 | 400.00 |

| 4" X SCH 40 | 600.00 |

| 6" X SCH 40 | 1350.00 |

| 8" X SCH 40 | 2400.00 |

| 10" X SCH 40 | 4500.00 |

| Country | Address |

|---|---|

UAE UAE |

Dubai |

UAE UAE |

Abu Dhabi |

Qatar Qatar |

Doha |

Saudi Arabia Saudi Arabia

|

Riyadh |

Saudi Arabia Saudi Arabia |

Jeddah |

Bahrain Bahrain |

Manama |

Kuwait Kuwait |

Kuwait City |

Oman Oman |

Muscat |

Saudi Arabia Saudi Arabia |

Eastern Province |

UAE UAE |

Sharjah |