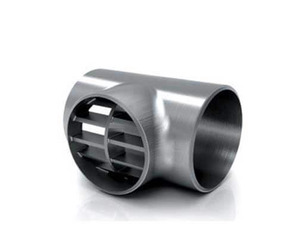

Introducing Rexon, your source for top-quality AISI 321/321H Stainless Steel ButtWelded Equal Tee Pipe Fittings. Crafted for peak performance in demanding industrial settings, these fittings offer exceptional corrosion resistance and high-temperature stability. Available in various sizes and configurations, Rexon delivers precision engineering, competitive pricing, and on-time delivery. Trust us for excellence in every connection, even in challenging conditions.

Rexon Pipe Fittings is a leading brand in manufacturing AISI 321 Stainless Steel ButtWelded Equal Tee pipe fittings. The company manufactures a wide range of butt-welded fittings and flanges that are used for oil and gas pipelines. These fittings are manufactured out of premium stainless steel that has high pressure and temperature endurance. The company also provides custom fittings based on the customer’s requirements.

The Standard Equal Tee is a tee fittings used to join three pipes with equal diameters. This method is a very simple and convenient way of joining three pipes together. This tee is widely used for plumbing and heating, in addition to industrial systems. It comes in different sizes as well as different materials, which are stainless steel, carbon steel and alloy steel.

Reducing Equal Tee is a special type of tee fitting that joins three pipes with different diameters. It is intended to yield a throttling of the flow in one pipe while preserving uniform flows through two other pipelines. This kind of tee is widely used in plumbing as well as heating systems, and also industries. You can find it in different sizes and materials such as stainless steel, carbon steel or alloyed.

A Barred Tee is a tee fitting that is based on a normal tee (can be either an equal tee or a reducing tee). At a later stage, bar plates are added inside the branch outlet to restrict the PIG (pipeline PIGGING) from flowing from the header pipe into the branch pipes.

The availability of stainless steel butt-welded tees makes them an important part of different industries as they are used to change the direction of flows, branching and adjustment in pipe diameters. The corrosion resistance, resilience and sustainability associated with them make the heavy applications such as oil & gas industry, chemical industry, pharmaceutical sector food and beverage processing unit and water treatment very convenient to manage.

| Specification | Description |

|---|---|

| Material Grade | 321 (UNS S32100) and 321H (UNS S32109) stainless steel |

| Size Range | Specified in nominal pipe sizes (NPS) or millimeters |

| Wall Thickness | Conforms to the appropriate standard (e.g., ASME B16.9) - Specified in schedule numbers or millimeters |

| Manufacturing Standards | Conforms to recognized standards, e.g., ASME B16.9 (for stainless steel fittings) |

| Pressure Rating | Varies with material, wall thickness, and size - Typically designated by class numbers (e.g., Class 150, Class 300) |

| End Connections | Beveled ends for welding - Bevel angle typically 37.5 degrees |

| Surface Finish | Exterior and interior surfaces free from defects - Welds properly formed and inspected |

| Heat Treatment | Post-weld heat treatment (PWHT) may be necessary for certain applications |

| Testing and Inspection | Visual inspection, dimensional checks, non-destructive testing (e.g., radiographic, ultrasonic) - Material testing (e.g., PMI) |

| Marking | Clearly marked with size, material grade, manufacturer's name/logo, and relevant standards |

| Certification | Manufacturer provides material certificates, test reports, and other documentation to confirm compliance with specifications and standards |

Equal Tee Buttweld Pipe Fittings in High-Quality Stainless Steel made are key elements to various industries for example those that use oil and gas, chemicals pharmaceutical foodstuffs beverages as well as water treatment. These end-fitting enhance the corrosion resistant strength and sustainability. These fittings vary according to the physical attributes due to their grade of stainless steel.

| Material | Rockwell Hardness (HRC) Range |

|---|---|

| Carbon Steel (ASTM A234) | 65-78 HRC |

| Stainless Steel (ASTM A403) | 70-95 HRC (varies by grade) |

| Alloy Steel (ASTM A234) | 70-85 HRC (varies by alloy) |

| Brass | 40-80 HRC (varies by alloy) |

| Copper | 45-99 HRC (varies by alloy) |

| PVC (Plastic) | Not applicable (non-metallic) |

| Cast Iron | 130-235 HRC (varies by grade) |

| Titanium | 70-36 HRC (varies by alloy) |

| Aluminum | 15-120 HRC (varies by alloy) |

| Inconel | 70-47 HRC (varies by alloy) |

| Monel | 70-31 HRC (varies by alloy) |

The principal industries that depend on Buttweld Tee Fittings fabricated from Stainless Steel are oil and gas, chemicals pharmaceuticals food and beverages as well as the field of water treatment. These are corrosion resistant, high strength and long lasting stainless steel fittings.

| Element | 347 Stainless Steel (%) | 347H Stainless Steel (%) |

|---|---|---|

| Carbon (C) | 0.08 max | 0.04 - 0.10 |

| Chromium (Cr) | 17.0 - 19.0 | 17.0 - 19.0 |

| Nickel (Ni) | 9.0 - 13.0 | 9.0 - 13.0 |

| Manganese (Mn) | 2.0 max | 2.0 max |

| Silicon (Si) | 0.75 max | 0.75 max |

| Phosphorus (P) | 0.045 max | 0.045 max |

| Sulfur (S) | 0.03 max | 0.03 max |

| Molybdenum (Mo) | 0.75 max | 0.75 max |

| Iron (Fe) | Balance | Balance |

| Description | Price In INR (Per Piece) |

|---|---|

| ASTM A403 WP | |

| 2" X SCH 40 | 325.00 |

| 3" X SCH 40 | 400.00 |

| 4" X SCH 40 | 600.00 |

| 6" X SCH 40 | 1350.00 |

| 8" X SCH 40 | 2400.00 |

| 10" X SCH 40 | 4500.00 |

| Country | Address |

|---|---|

UAE UAE |

Dubai |

UAE UAE |

Abu Dhabi |

Qatar Qatar |

Doha |

Saudi Arabia Saudi Arabia

|

Riyadh |

Saudi Arabia Saudi Arabia |

Jeddah |

Bahrain Bahrain |

Manama |

Kuwait Kuwait |

Kuwait City |

Oman Oman |

Muscat |

Saudi Arabia Saudi Arabia |

Eastern Province |

UAE UAE |

Sharjah |