Oman's Rexon Pipe Fittings, the best-in-class manufacturer and exporter of 316 Stainless Steel Butt-Welded Pipe Fittings, excels in both its production and export to Oman and other countries. Considering the importance of accuracy, one of the success factors being superior quality and best technology skills is maintained to show up that our fittings fulfill the highest industry standards. Our vision is to develop long-lasting and trustworthy solutions. Our products are designed to be used in harsh environments with the veracity and quality that our users demand. Whether you are an industrialist, a contractor, or you simply need high quality fittings for your home, our comprehensive range of fittings are customized for different needs with precision and efficiency. Through Rexon Pipe Fittings, customers can be sure of products that are of the highest standards, guaranteed to last, and work without any complications. While working with our 316 Stainless Steel Butt-Welded Pipe Fittings you can be assured to meet the highest levels of reliability and efficiency in Oman and beyond.

316 Elbow SS Butt-Welded Connections are high-quality stainless steel fittings created for cost-free, straight pipework and piping array. This type of fittings comes with better strength, resistance to corrosion and their applications in many industries are safe and long lasting.

316 Tee SS welded fittings is a stainless steel fitting that is manufactured for put together or merging three other pipes at 90degrees angles. Theses fittings are used in the making from the high-quality 316 stainless steel, the alloy offers very excellent corrosion resistance and durability inside the different industrial operations.

Our butt welded, tested and verified 316 Reducer SS Fittings guarantee quick and easy connections in piping systems with the highest reliability and durability available. Generated by the process of stainless steel, these fittings are designed to be leak-free and to facilitate smooth flow management in various industrial operations.

These 316 End Cap SS Butt Welded Fittings render a convenient, leak-free range for terminating the stainless steel pipe line. Designed to precise high-durability standards, these fittings will to assure a tight seal fitting for applications in industries.

The 316 Stub End SS Butt-Welded Fittings are vitally important parts for connecting different diameter pipes together so that there is a sure and leak-proof joint. Built of the corrosion resistant SS316 which is often used in industrials application, these fittings show higher durability than others common not containing SS316.

316 outlet stainless steel butt welded fittings are the types of fittings that are created to be used to branch off pipelines. The framework of this material is from a high-grade 316 stainless steel that provides high resistance to corrosion and durability, making it appropriable for various industries.

Stainless steel pipe fittings in Oman find applications in plumbing, heating, and chemical processing industries, with selection based on specific applications and site-specific requirements.

Rexon Pipe Fittings will provide a comprehensive variety of 316 stainless steel butt welded fittings, including elbows, tees, reducers, and end caps. Our fittings, created with absolute accuracy, install effortlessly and deliver optimum results in the demanding world of industrial tasks. When made to meet strict quality norms, they prove to be not only resistant to corrosion but also durable. Our customers can be assured of high reliability and efficiency when they choose Rexon Pipe Fittings, the part they can trust for all their flexible and stainless steel piping solutions.

Rexon Pipe Fittings provides top-notch 316 Stainless Steel standard butt-welded fittings that pass strict tests on their performance and stability. 316 stainless steel corrosion-proof fittings manufactured are part of our offerings for harsh conditions and guarantee long-term dependability. These fittings being engineer exactly to precise specification allow leak free connections and clean integration between other components. With Brand and materials from Rexon Pipe you can rely on the precision and quality of our products. Our products are ideal for various industries such as petrochemical, chemical processing and marine. Choosing Rexon for outstanding 316 Stainless Steel Butt-welded fittings that beat the market will be your best decision.

| Butwelded Type | Butt-welded Fitting Standard |

|---|---|

| Type Of Fittings | 45 Deg, 90 Deg , 180 Deg. |

| Size | 1/2"NB TO 48"NB IN |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated |

| Grades | |

| Nickel Alloy | ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 (ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

| Stainless Steel | ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304 H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H. |

| Carbon Steel | ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Alloy Steel | ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91. |

| Duplex Steel | ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760. |

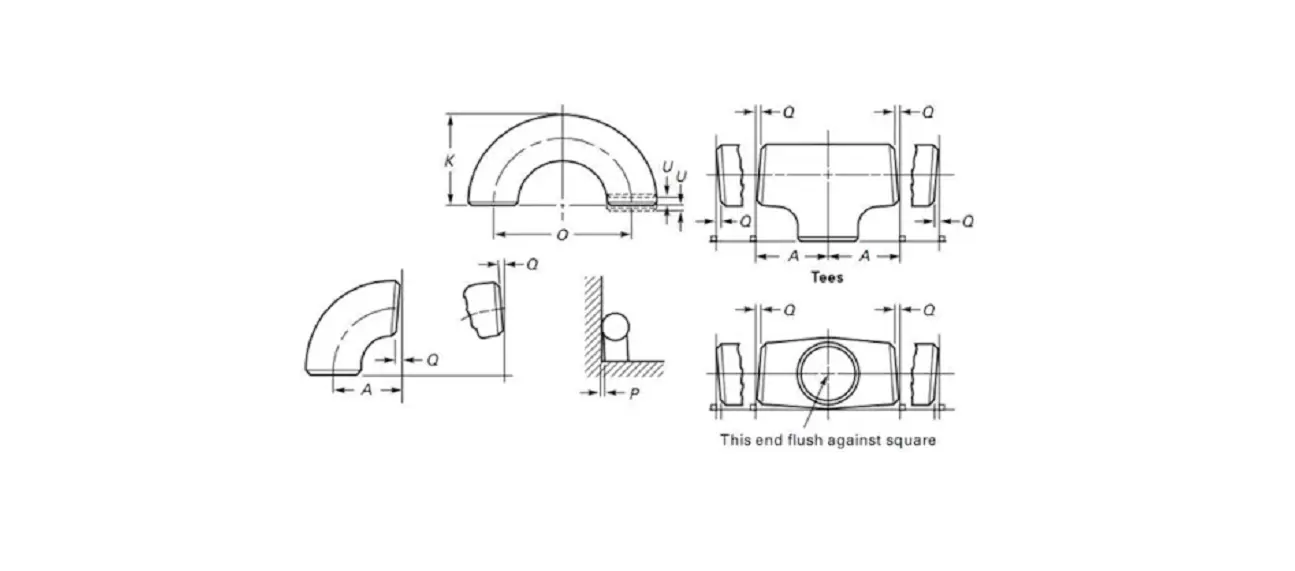

Rexon Pipe Fittings offers a meticulous schematic for butt welded stainless steel fittings as shown in the illustration below. These show how the fittings are well-connected together in piping systems. Through highlighted diagram we demonstrate would be precision welding , and also ensure leak proof joints that meet in industry standards. Rexon Pipe Fittings customers can now sail through procedures and configurations with everything being clear, and work will be done efficiently and effective to achieve the desired end result.

Rexon Pipe Fittings produces premier standard 31 6 ss butt welded pipe fittings which are highly resistant to corrosion and have a long service life period. These fittings are composed of alloy of 16-18% chromium, 10-15% nickel, and a small quantity of molybdenum besides the carbon content being on order of two to three percent. Both these materials, together, exhibit high resistance to different corrosive environments and hence, be it chemical processing, marine, or oil & gas industries, they are ideally suited for such demanding applications. Quality follows Rexon to guarantee that its piping fittings meet the highest standards and work effectively under pressure in any environment.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 - 26.00 | 0.10 max | 19.00 - 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 - 26.00 | 0.75 max | 19.00 - 21.00 | 53.095 min |

| SS 310H | 0.04 – 0.10 | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 - 26.00 | - | 19.00 - 21.00 | 53.885 min |

Rexon Pipe Fittings provides 316 SS Buttweld Pipe Fittings of excellent quality, which are known for their superior physical properties. Moreover, these fittings are not vulnerable to the corrosive environment, so they can be used in the tough conditions. They, having a good contrast to pitting and crevice corrosion, extend the service life in any given conditions. Also, 316 Stainless Steel has exceptional strength and toughness while it keeps its formability and weldability very well. Rexon Pipe Fittings ensures industry-wide dependable services of robust piping systems, thereby, making operations optimal and durable.

| Grade | Tensile Str (MPa) min |

Yield Str 0.2% Proof (MPa) min |

Elong (% in 50mm) min |

Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40 | 95 | 217 |

| 316L | 485 | 170 | 40 | 95 | 217 |

| 316H | 515 | 205 | 40 | 95 | 217 |

The dispatch of the price list comprising 316 SS Butt-welded Pipe Fittings from Rexon Pipe Fittings for the period beginning from 1st February 2024. Our fittings come in a wide variety, providing you with options that offer the best quality and durability in fulfilling your piping needs. As we take our position against the competition, Rexon Pipe Fittings commits to affordable price and industry standard integrity, just as our client and partner. Be the leader through your superb quality and reliability. Contact us now to get the complete price-list and simplify your procurement process.

| Description | Price In INR (Per Piece) |

|---|---|

| ASTM A403 WP | |

| 2" X SCH 40 | 325.00 |

| 3" X SCH 40 | 400.00 |

| 4" X SCH 40 | 600.00 |

| 6" X SCH 40 | 1350.00 |

| 8" X SCH 40 | 2400.00 |

| 10" X SCH 40 | 4500.00 |

| Country | Address |

|---|---|

UAE UAE |

Dubai |

UAE UAE |

Abu Dhabi |

Qatar Qatar |

Doha |

Saudi Arabia Saudi Arabia

|

Riyadh |

Saudi Arabia Saudi Arabia |

Jeddah |

Bahrain Bahrain |

Manama |

Kuwait Kuwait |

Kuwait City |

Oman Oman |

Muscat |

Saudi Arabia Saudi Arabia |

Eastern Province |

UAE UAE |

Sharjah |