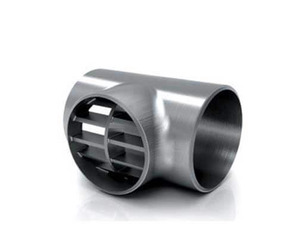

Rexon Pipe Fittings is one of the leading manufacturers of AISI 304 Stainless Steel ButtWelded Equal Tee Pipe Fitting. The product is a stainless steel paint which can sustain high pressures and temperature. Fittings are manufactured in various dimensions and forms that include elbow, tee, reducer, end cap, cross, and stub end. The firm provides tailor-made fittings to the client's specifications. The fittings are of superior stainless steel and can withstand high pressure and temperature levels. The product is durable and therefore a perfect alternative for the oil and gas pipelines. Using quality pipe fittings is critical in guaranteeing the safety and effectiveness of a pipeline. Rexon Pipe Fittings delivers quality products to its clients. ButtWelded Equal Tee Pipe Fitting AISI 304 Stainless Steel is a kind of pipe fitting that connects three pipes with the same diameter. While the product is made up of quality stainless steel and can withstand high pressures and temperatures.

These fittings come in different forms and shapes such as elbow, tee, reducer, end cap, cross and stub end. Rexon Pipe Fittings is a leading brand in the manufacture of AISI 304 Stainless Steel ButtWelded Equal Tee pipe fitting. The firm provides various butt-welded fittings and flanges of oil and gas pipelines. The fixtures are manufactured with premium-quality stainless steel and have a high pressure and temperature resistance. The company also provides personalized fittings according to the clients' needs.

The Standard Equal Tee tee fitting is used to connect three pipes with equal diameters. This is a simple and cost-effective method of connecting three pipes. This tee is usually found in the piping of plumbing and heating systems as well as industries. It is available in various sizes including stainless steel, carbon steel and alloy steel.

The term Reducing Equal Tee pertains to a tee-fitting that joins three pipes with different diameters. Yet it seeks to reduce the amount of fluid or gas in one pipe such that the flow rate through each of other pipes remains constant. This tee is used in plumbing and heating systems, as well industrial process'. It is offered in various coefficients and materials including stainless steel, carbon steel alloyed steels.

A Barred Tee is a special type of tee fitting that is based on a normal tee (can be either an equal tee or a reducing tee). At a later stage, bar plates are added inside the branch outlet to restrict the PIG (pipeline PIGGING) from flowing from the header pipe into the branch pipes.

Butt-welded tee pipe fittings made out of stainless steel play a very important role across different industries since they are used for changing the direction of flows, branching and even alterations to pipe diameters. They are particularly suited for heavy applications including in the oil and gas, chemical, pharmaceutical, food and beverage and water treatment industries due to their corrosion resilience (strength) as well as sustainability.

| Standards | ASME SA403 &ndash , ASTM A403 – ANSI – B 16.9; API 590-605, ASME B16.9 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’, ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short ; Factory-Made Wrought Buttwelding Fittings”, ASME B16.25 – ‘ Radius Elbows and Returns’, MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

|---|---|

| Schedule | Sch 5 TO Sch XXS. |

| Sizes | 1/2"NB TO 48"NB IN / 1/2” TO 36”, (SEAMLESS UPTO 24”), (WELDED 8” TO 36” ) |

| Materials | Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type | Fabricated / ERW / Welded / Seamless / Butt Weld (BW) |

| Thickness | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension | Outside diameter : 1/2" à 24", (21,34 – 609,5 mm), Thickness : SCH 5S, 10S, 40S (STD), 80S (XS), 160, XXS, (1,65 – 59.51 mm) |

| Variations | Seamless & Welded |

Equal Tee Buttweld Pipe Fittings in High-Quality Stainless Steel made are key elements to various industries for example those that use oil and gas, chemicals pharmaceutical foodstuffs beverages as well as water treatment. These end-fitting enhance the corrosion resistant strength and sustainability. These fittings vary according to the physical attributes due to their grade of stainless steel.

| Material | Rockwell Hardness (HRC) Range |

|---|---|

| Carbon Steel (ASTM A234) | 65-78 HRC |

| Stainless Steel (ASTM A403) | 70-95 HRC (varies by grade) |

| Alloy Steel (ASTM A234) | 70-85 HRC (varies by alloy) |

| Brass | 40-80 HRC (varies by alloy) |

| Copper | 45-99 HRC (varies by alloy) |

| PVC (Plastic) | Not applicable (non-metallic) |

| Cast Iron | 130-235 HRC (varies by grade) |

| Titanium | 70-36 HRC (varies by alloy) |

| Aluminum | 15-120 HRC (varies by alloy) |

| Inconel | 70-47 HRC (varies by alloy) |

| Monel | 70-31 HRC (varies by alloy) |

The principal industries that depend on Buttweld Tee Fittings fabricated from Stainless Steel are oil and gas, chemicals pharmaceuticals food and beverages as well as the field of water treatment. These are corrosion resistant, high strength and long lasting stainless steel fittings.

| Element | 347 Stainless Steel (%) | 347H Stainless Steel (%) |

|---|---|---|

| Carbon (C) | 0.08 max | 0.04 - 0.10 |

| Chromium (Cr) | 17.0 - 19.0 | 17.0 - 19.0 |

| Nickel (Ni) | 9.0 - 13.0 | 9.0 - 13.0 |

| Manganese (Mn) | 2.0 max | 2.0 max |

| Silicon (Si) | 0.75 max | 0.75 max |

| Phosphorus (P) | 0.045 max | 0.045 max |

| Sulfur (S) | 0.03 max | 0.03 max |

| Molybdenum (Mo) | 0.75 max | 0.75 max |

| Iron (Fe) | Balance | Balance |

| Description | Price In INR (Per Piece) |

|---|---|

| ASTM A403 WP | |

| 2" X SCH 40 | 325.00 |

| 3" X SCH 40 | 400.00 |

| 4" X SCH 40 | 600.00 |

| 6" X SCH 40 | 1350.00 |

| 8" X SCH 40 | 2400.00 |

| 10" X SCH 40 | 4500.00 |

| Country | Address |

|---|---|

UAE UAE |

Dubai |

UAE UAE |

Abu Dhabi |

Qatar Qatar |

Doha |

Saudi Arabia Saudi Arabia

|

Riyadh |

Saudi Arabia Saudi Arabia |

Jeddah |

Bahrain Bahrain |

Manama |

Kuwait Kuwait |

Kuwait City |

Oman Oman |

Muscat |

Saudi Arabia Saudi Arabia |

Eastern Province |

UAE UAE |

Sharjah |