In Oman, where the demand for high-quality products is considerably higher, Rexon remains a company that produces SS butt-welded pipe fittings of unparalleled standing. The brand has been associated with a strong presence of quality that was made possible by the firm’s commitment since its first time. Rexon, being one of the leading manufacturers and exporters in its niche boasts of a record in delivery services that undergo through national quality procedures. Among such products, presented in our extensive catalog are stainless steel butt-welded pipe fittings including elbows, tees, reducers, caps etc.; flanges of all types and sizes; gaskets for various purposes; different grades of steel pipes. The main products of Rexon company include the SS butt weld pipe fittings; these leverages high materials for production including the carbon steel, stainless steel, alloy steel, and duplex steal. These fittings are some of a kind in that they have been manufactured to meet various needs of the industrial set up such as industries like oil and gas, petrochemicals, power generation, water treatment and other industries around. The vow that we all make to deliver quality products assures of efficient workability for a long time with best performance, we offer our broad range of butt-welded pipe fittings that have been made for fully customization.

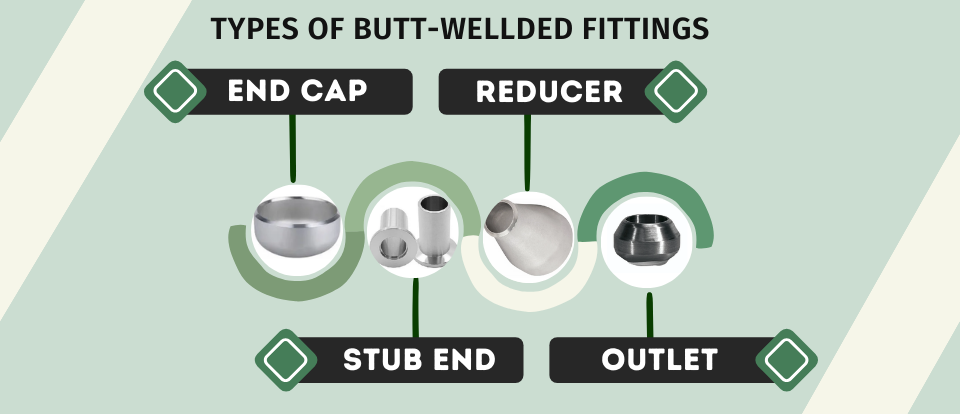

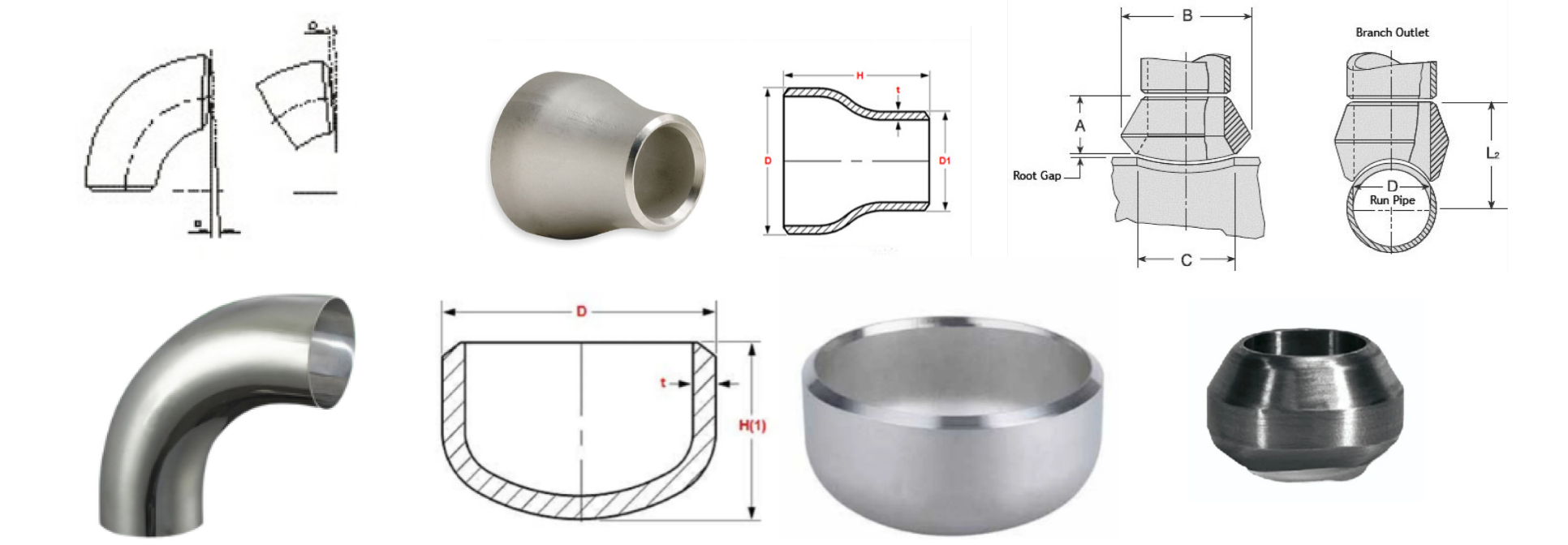

They operate as vital pipe connective for pipes with different sizes and shapes. Carefully constructed using superior standard stainless steel, the following fittings are resistant to high pressure and temperature. The product line consists of elbows, tees, reducers and caps all of which have a definite task related to making sure the fluid moves through it. The bend introduces flow angle change due to elbows within a pipe system whereas tees allow the split or combination of 3 right angled pipes with use. The existence of reducers makes it easier to connect pipes of varying diameters and the presence of caps provides a tight seal to prevent any leakages through pipe ends. In addition to their basic functions, butt welded pipe fuse joints are widely used in oil and gas chemical industry as well as petrochemical. According to their resistance in gaining corrosion and hardness, SS butt-welded pipe fittings are more effective compared to other types of fittings.

The elbow butt-welded fittings from Rexon go beyond being just parts: they stand in for engineering solutions whose very direction of flow can be orchestrally changed. Our devotion does not only include production of differing angles, size and stainless steel grades such as 304, 316 and 317.

With Rexon butt-welded fittings, you are not merely looking at a joint for making unions; these parts symbolize engineered solutions to provide the perfect and seamless connection. Our products are designed especially for stainless steel grades 304, 316, and 321 to serve the best needs.

Butt-welded fittings produced by Rexon are designed to take over the traditional function of a pipe connector where the individual promotes joining in respect to its diameter. Working in varying sizes and grades such as Stainless Steel 304, 316, and Stainless Steel 321.

The butt-welded fittings supplied by Rexon far exceeds the simplest function of being pipe terminator as these are very carefully elaborated solutions to improve closures between open ends and bodies. Comprising a wide range of nominal dimensions and grades such as 304, 316,and 321 stainless steel variant.

The Rexon-produced flanged buttwelds involve more than connections with pipes fittings; they are diligently designed to ensure that the fittings are flanged in a secure manner. The products are manufactured as per different sizes in Oman from a wide range of stainless steel grades with value-added characteristics which come under 304, 316S and indicated principles or manufacturing that includes safety measures.

The special process fittings employed in this connection are aimed at the linkage between a branch pipe and a run pipe at an angle. Cushion rubbers locally produced in Oman come in diverse sizes to meet different industrial demands. The locally produced fittings provide accurate and effective connection of pipes in various uses like photographic laboratories.

stainless steel butt-welded fittings have more advantages than simply strength. They are made from stainless steel which is a material reputed for its resistance to corrosion. This quality gives these pipes a significant edge over the others as they are best suited for the situations where the pipes are exposed to chemicals, saltwater or extreme temperatures. From oil and gas refineries to food and beverage factories, these fittings should bring long-term value to the user without experiencing any kind of rust or degradation. Weldable connecting elements are crucially important for piping systems; these devices ensure a welded connection between pipes and other components using full butt weld fittings. The metal pieces are well-made from high-quality steel, thus reflecting their inertness to large amounts of heat and pressure. Such typical ones include elbows, tees and reducer caps. Rexon Pipe Fittings – manufacturer and supplier major in Oman stands as a brand name for high-quality SS Butt Welded Solutions, required to meet various industrial applications.

Steel butt-welded fittings are the high-end type that people aspire to get and they are also part of one of the roles because steel forms a crucial role in connecting pipes with rigid joints that can resist temperatures and pressures from inside piping systems. Rexon Pipe Fittings, a renowned manufacturer in Oman that follows set standards such as ASME B16.9 for Carbon and Alloy configurations, MSS SP 43 for Duplex, Spiral-Wound and Nickel-alloyed tops crafts abide by these norms. There, the firm uses an exceptional butt-welded option that is capable of performing well in different industrial processes.

| Butwelded Type | Butt-welded Fitting Standard |

|---|---|

| Type Of Fittings | 45 Deg, 90 Deg , 180 Deg. |

| Size | 1/2"NB TO 48"NB IN |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated |

| Grades | |

| Nickel Alloy | ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 (ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

| Stainless Steel | ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H. |

| Carbon Steel | ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Alloy Steel | ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91. |

| Duplex Steel | ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760. |

High-order stainless steel nowadays has become the master of inconstant deliverances, especially when we speak about manufacture’s butt-welded pipe fittings. This glass / cool tube is structured with the use of amazingly durable stainless steel that shows how strong it can be as they resist nothermo loads and pressure. Marked changes in chemical compositions of the stainless steel grades used as these fittings readily distinguish it.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 - 26.00 | 0.10 max | 19.00 - 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 - 26.00 | 0.75 max | 19.00 - 21.00 | 53.095 min |

| SS 310H | 0.04 – 0.10 | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 - 26.00 | - | 19.00 - 21.00 | 53.885 min |

Pipe fittings are butt welded and they act as generic weldable parts used to connect pipes, among others found in a pipeline. From high-grade stainless steel, the fittings come provide superior tolerance to extreme temperature and pressures. In manufacturing SS butt-welded pipe fittings, the mechanical characteristics of FS13 material used by different grades differs. The common grades of stainless steel such as, 304 HD ,the properties include density, melting point;thermal and electro conduction etc.Likewise For 316 the requirements are more than just typical function things iqe specifications like percent drop highest frequency basket wave observed waffle iron magnetic flux cr jeho k?Titualni pose s í nad Melting point density of stainless steel is about 7.8 to 8.05 g/cm³ and ranges between the temperaturesof1398°Cand1454 ° C.. Thermal conductivity is about 14, whereas electrical conductivity values are from 1.25 × S m to 3high moderate than that of phospholipids lipid tethered surface plasma resonance hightly and low band nano materislayer photocatalytlc materialsbacteria l yoga sumsamin estimated total costing smart junit Rexon pipe fittings, which comprises a major part of the market in manufacturing and supplying stored stainless butt-welded pipe fittings to Oman holds its leading position.

| Grade | Density (kilogram/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity(W/m.K) | Specific Heat 0-1000C(J/kilogram.K) | Electrical Resistivity (n.m) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| ASTM A403 WP 304 Elbow | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

The weldable piping components, prior to butt-welding are identified with the prospect of welding pipe and also other system elements successfully. Made from premium stainless steel that is famed for surviving high temperatures and pressure these elements are essential in pipelines. The prices of SS butt welded pipe fitting are dye; stainless steel grade, size greater count can be the factors that influence this parameter. However, though a lot of the websites that give price lists for these fittings are many however prices may change owing to market interactions and any other factor deemed necessary.

| Description | Price In INR (Per Piece) |

|---|---|

| ASTM A403 WP | |

| 2" X SCH 40 | 325.00 |

| 3" X SCH 40 | 400.00 |

| 4" X SCH 40 | 600.00 |

| 6" X SCH 40 | 1350.00 |

| 8" X SCH 40 | 2400.00 |

| 10" X SCH 40 | 4500.00 |

| Country | Address |

|---|---|

UAE UAE |

Dubai |

UAE UAE |

Abu Dhabi |

Qatar Qatar |

Doha |

Saudi Arabia Saudi Arabia

|

Riyadh |

Saudi Arabia Saudi Arabia |

Jeddah |

Bahrain Bahrain |

Manama |

Kuwait Kuwait |

Kuwait City |

Oman Oman |

Muscat |

Saudi Arabia Saudi Arabia |

Eastern Province |

UAE UAE |

Sharjah |